Material and strengthening of mobile phone protective film glass

Nov 12,2022 | Jeff

Common glasses include lithium-aluminum glass, soda-lime glass, and high-alumina glass. The cost of lithium-aluminum glass is high, and only a few high-end products have applications, such as Corning Gorilla 5. The coefficient is relatively large, ion exchange can be accelerated in chemical tempering, and the strength can be higher, so high aluminum is the mainstream choice for high-end products.

The key is to strengthen.The strengthening method includes chemical strengthening, soaking in molten salt at 400 degrees Celsius, the larger potassium ions in the molten salt will exchange with the smaller sodium ions in the glass, which is the volume expansion of the glass surface, resulting in a crowding phenomenon.

Form a lamination stress and increase the strength. Most of the films on the market can be called tempered films. However, in order to further improve, it is necessary to solve the small cracks generated on the glass surface in the previous step. These small cracks are the result of tempering.

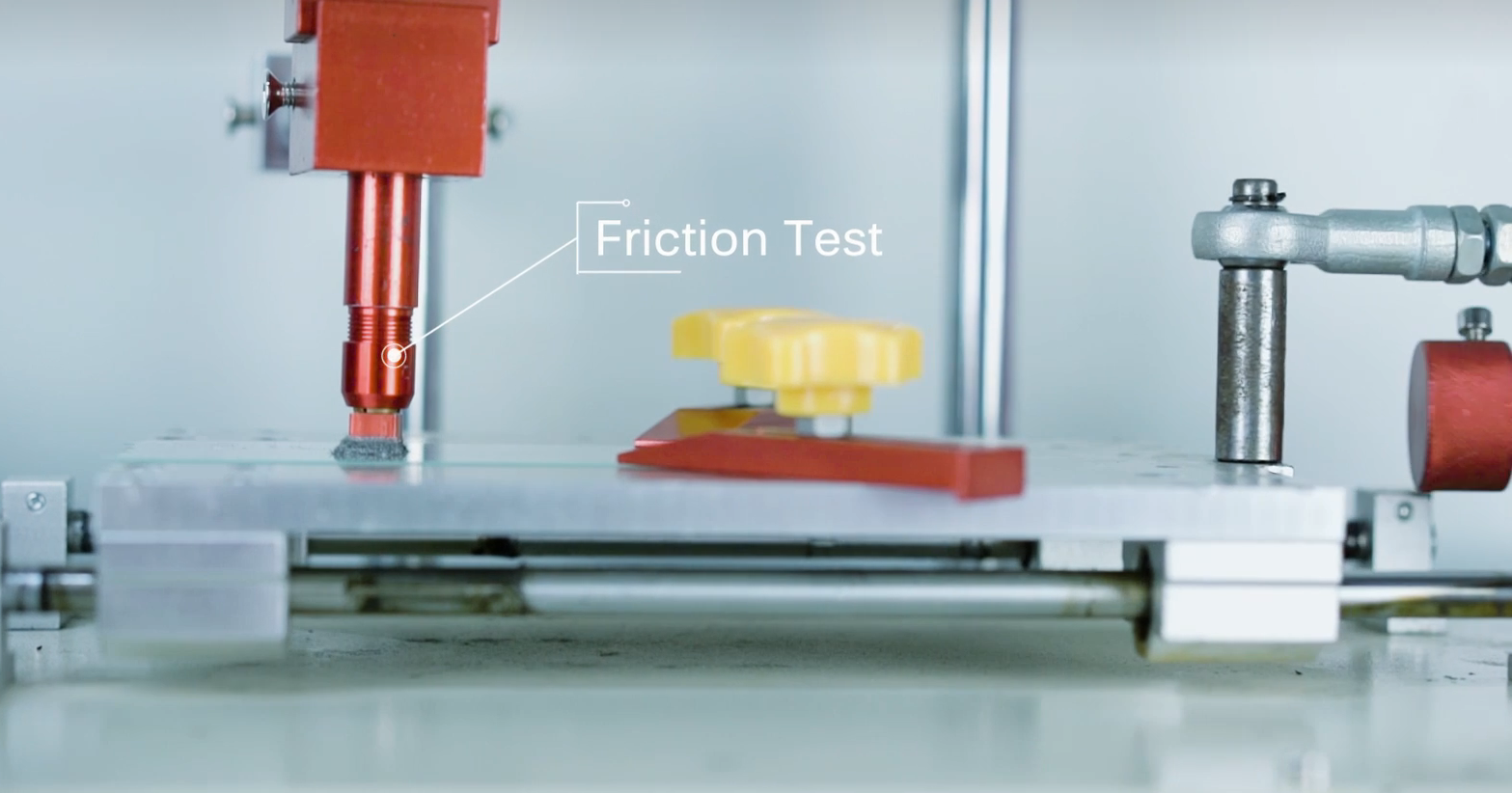

There is a hidden danger of film breakage, so it is necessary to chemically polish the glass surface with a solution containing hydrofluoric acid, or use a high-precision edger to eliminate cracks and defects on the glass surface through long-term grinding. The industry is known as the second strong. A falling ball is usually used to test the strength of the center, and a manometer is used to test the strength of the edge.