The special production process of curved screen mobile phone film

Oct 21,2022 | Jeff

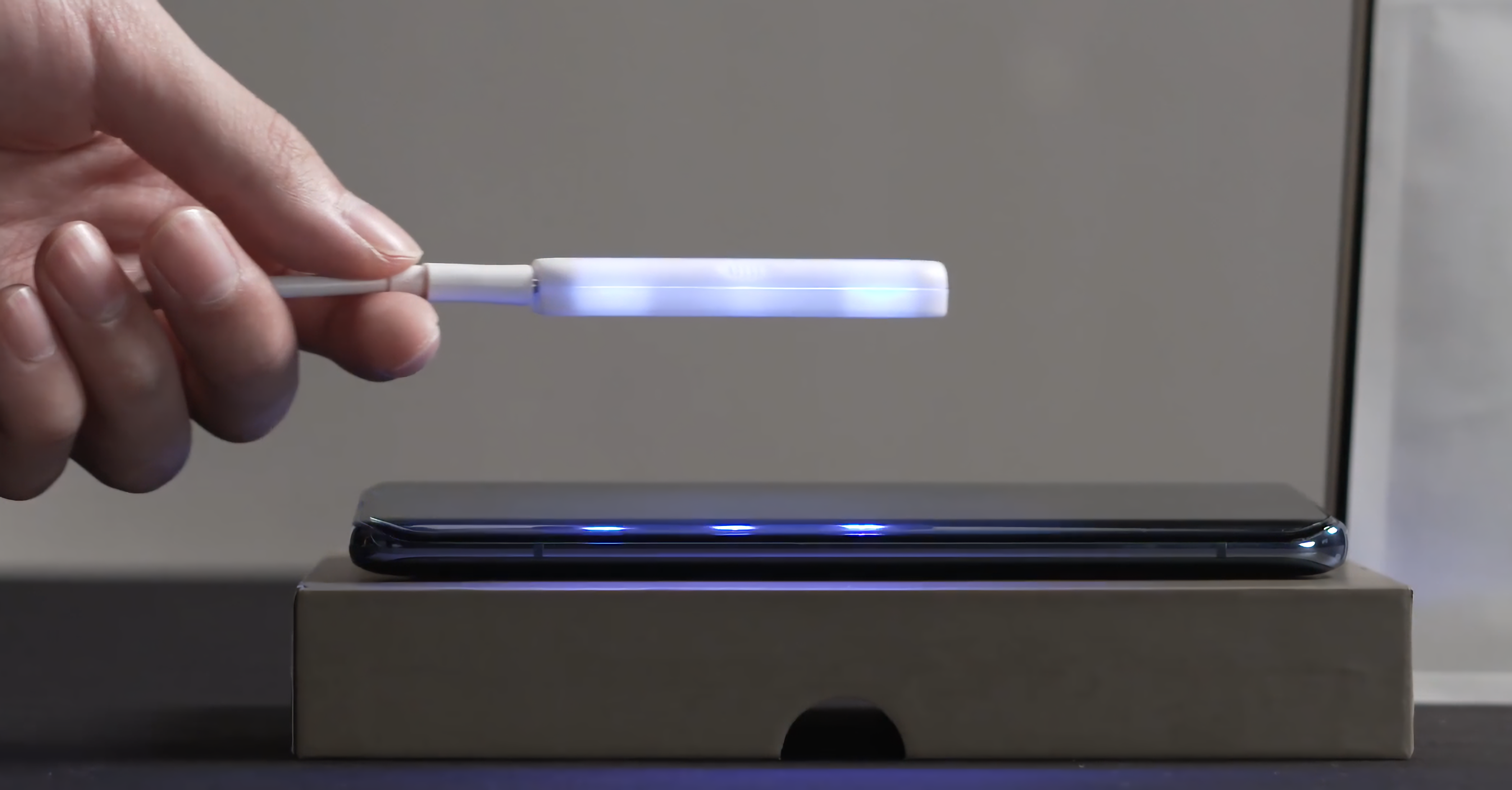

In March 2015, Samsung released its first curved screen phone, the epoch-making Samsung S6 Edge. Since then, mobile phones in this world have been divided into two categories according to the screen: straight-screen mobile phones and curved-screen mobile phones.

So what are the benefits of a curved screen phone? In terms of appearance, it is still very beautiful. The most important thing is that there is no sense of restraint with black borders on the left and right. It is visually very simple and round, giving people an inexplicable sense of comfort and fullness. Psychologically, many people feel that the surface grade is also higher.

Of course, the curved screen also has its disadvantages. The left and right edges are obviously green, and the display is somewhat deformed. There is also the bad operation and game experience caused by mistaken touch! The most uncomfortable disadvantage should be that the curved screen is more prone to explosion, and the cost of replacing the screen is high, but it is difficult to apply the film!

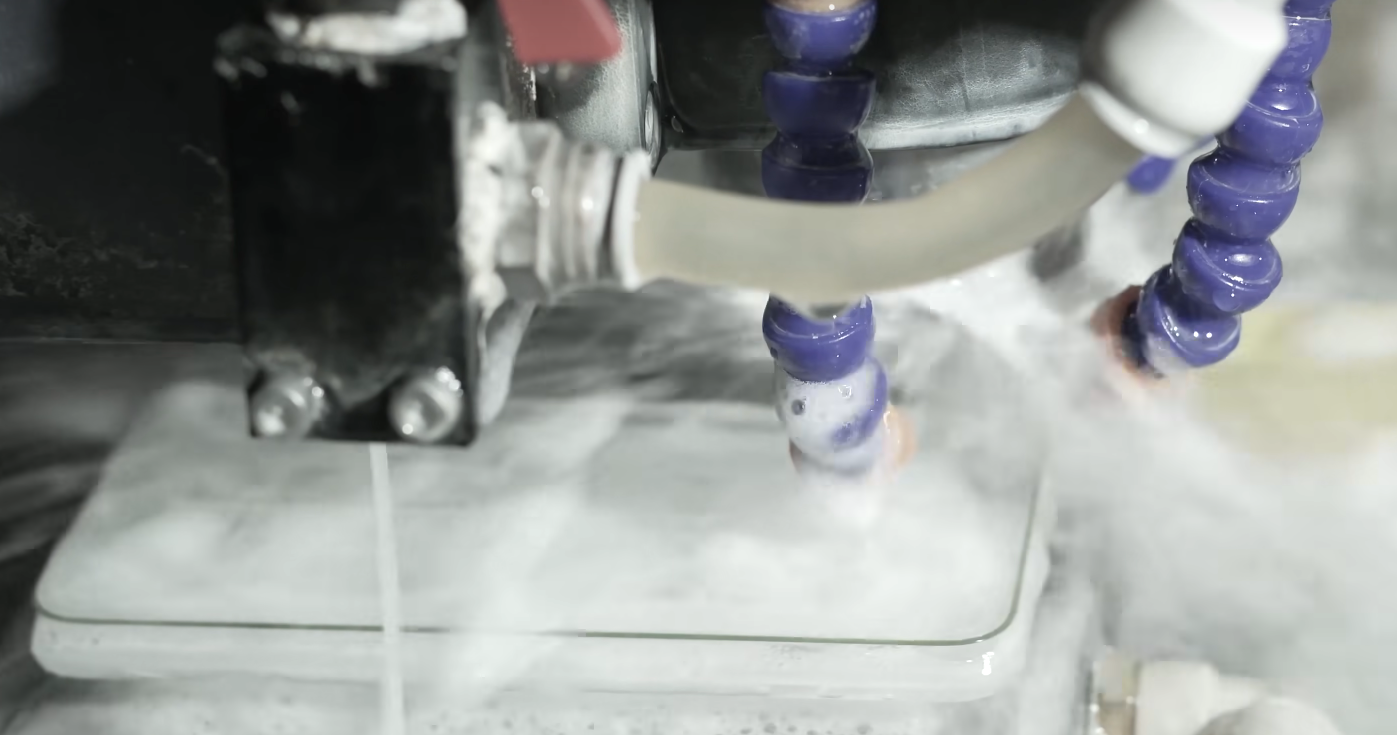

In order to protect the curved screen, a cold engraving process is added to the processing technology of the mobile phone film. The CNC engraving machine grinds the glass to the corresponding arc, but any damage to the glass surface will reduce the strength of the glass. After thousands of CNC engravings, the strength of a piece of glass has dropped significantly.

So, in order to solve this problem, another process turns up, hot bending. First, the glass film is placed on the graphite mold, heated to a high temperature of 600 degrees Celsius in a hot bending machine, and then the glass is softened and formed, and taken out after cooling.

But this method is too costly, high losses from graphite molds and high manufacturing costs. Therefore, the process of dispensing appeared again. Epoxy glue was dropped on the edge of the flat glass film through a dispensing machine, and after being baked at a high temperature in a tunnel furnace, the glue was tightly combined with the glass, and then the inside-arc surface was processed by a CNC engraving machine.

In conclusion, in terms of the realization of full coverage of tempered film, hot bending is undoubtedly the best for us. However, based on the properties of consumables of protective film, dispensing is more suitable for us in terms of price.